Pressure swing adsorption technology is widely used in the separation, recovery, purification and concentration of industrial gases. This blog post will introduce the application of activated carbon in PSA, the selection of activated carbon, etc.

Pressure swing adsorption technology is widely used in the separation, recovery, purification and concentration of industrial gases. Its principle is based on the fact that the adsorbent can selectively adsorb impurities. Usually, the useful components will not be adsorbed during the adsorption process and can be highly purified for recycling. PSA is mainly applied for petrochemical, fertilizer, metallurgy, coal, food industries and other industries.

Derun has proven technical effectiveness and reliability for your gas separation and purification needs.

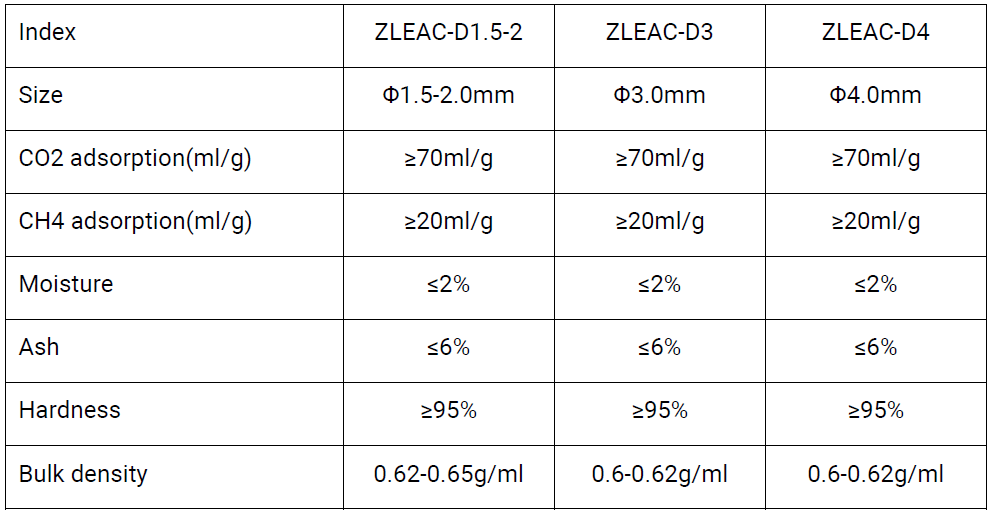

Pressure swing adsorption activated carbon uses low ash anthracite coal as raw material, after crushing it to 200mesh, adding a composite catalyst and coal tar, kneading with appropriate water, and then extruding it into a columnar shape in a molding machine. Then it is undergoing carbonization, acidification, activation and other processes to form special activated carbon. Catalyst will affect the molecular structure of the raw material and improves the micropore distribution of activated carbon.

It is mainly used in PSA hydrogen production plants in the petrochemical industry, industrial gas purification (purification of hydrogen, production of CO, CO2, nitrogen, CH4 and hydrocarbons in mixed gas), etc., and its regeneration effect is very good.

The adsorbents used in industrial PSA hydrogen production units are all solid particles with large specific surface areas, mainly including activated alumina, silica gel, activated carbon, and molecular sieves. Different adsorbents have different pore size distributions and adsorption capacities.

Derun generally provides 1.5mm activated carbon, which is filled in the middle of the adsorption tower and is mainly used to remove CO2 and CO components.

Oxygen is an important industrial gas. It is widely used in steel, non-ferrous metallurgy, the chemical industry, glass, sewage treatment, waste incineration, and other industries. The pressure swing adsorption oxygen production process (referred to as VPSA- O₂) is a low-cost oxygen enrichment technology. The principle is to use the blower to pressurize the raw material air into the adsorption tower.

Impurity gases such as N₂ are preferentially adsorbed by molecular sieves, and O₂ is enriched at the top of the adsorption tower as product output.

When the molecular sieve adsorption is saturated, the vacuum pump is switched through the valve to evacuate the adsorption tower to restore the adsorption capacity of the molecular sieve bed. In general, two adsorption towers are used in industry to circulate for achieving a continuous output of O₂ production.

What Are The Differences Between Impregnated Activated Carbon And Ordinary Activated Carbon?

Application of coal-based activated carbon in environmental protection field

The Principle And Effect of Activated Carbon Adsorption of Formaldehyde

Application of coal-based activated carbon in flue gas desulfurization and denitrification